What is SCADA?

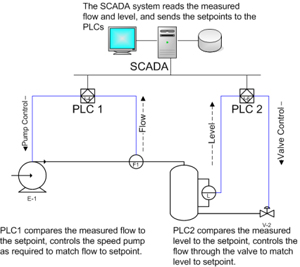

The

SCADA acronym stands for Supervisory Control and Data Acquisition.

SCADA systems are commonly used for utility companies such as electric,

water, and gas. The general idea for these systems is to be able to

monitor and control some level or status using programmable logic

controllers (PLCs) or remote terminal units (RTUs) and report it back

to a main server or master station. The master station can be

programmed to use this information to control other operations or just

to monitor the data. The data is distriubuted over a network to Human

Machine Interfaces (HMIs). The

SCADA acronym stands for Supervisory Control and Data Acquisition.

SCADA systems are commonly used for utility companies such as electric,

water, and gas. The general idea for these systems is to be able to

monitor and control some level or status using programmable logic

controllers (PLCs) or remote terminal units (RTUs) and report it back

to a main server or master station. The master station can be

programmed to use this information to control other operations or just

to monitor the data. The data is distriubuted over a network to Human

Machine Interfaces (HMIs).

HMI

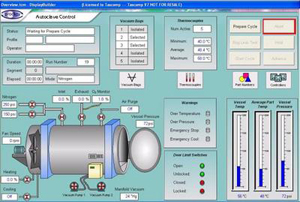

The

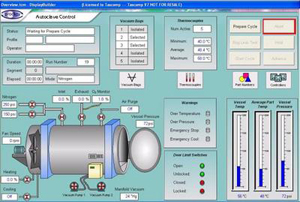

HMI is merely a computer with special software allowing a graphical

user interface into the SCADA system. The screen shot (Left) is one

example of an HMI software package. There are several guages and input

fields on the screen. The input fields could be used to send commands

to the remote units to control flow of air, water, or some chemical. The

HMI is merely a computer with special software allowing a graphical

user interface into the SCADA system. The screen shot (Left) is one

example of an HMI software package. There are several guages and input

fields on the screen. The input fields could be used to send commands

to the remote units to control flow of air, water, or some chemical.

HMI

software packages vary widely in looks and functionality. The system

that the City uses is vastly different than that shown in the example.

The City actually uses two different types of display screens. One is

called a single line diagram or SLD and the other is the updated

WorldView package offered by the SCADA vendor, QEI.

PLC

The

remote terminal unit (RTU) or programmable logic controller (PLC) is

the device out in the field that is collecting data and controlling

other devices such as valves or breakers. In general, the City uses

RTUs out in the field rather than PLCs (Left). There are significant

differences between the two although many manufacturers are building

them to be very similar. The typical RTU was designed to have inputs

for status such as door, valve, and breaker positions (digital data) as

well as flow rates or electrical current output (analog data). It will

also have some control functions to be able to open and close breakers

and valves and such. The

remote terminal unit (RTU) or programmable logic controller (PLC) is

the device out in the field that is collecting data and controlling

other devices such as valves or breakers. In general, the City uses

RTUs out in the field rather than PLCs (Left). There are significant

differences between the two although many manufacturers are building

them to be very similar. The typical RTU was designed to have inputs

for status such as door, valve, and breaker positions (digital data) as

well as flow rates or electrical current output (analog data). It will

also have some control functions to be able to open and close breakers

and valves and such.

PLC Programming

The

PLC has all those abilities with some small differences, but one major

difference is that PLCs are programmable. The program is usually a

ladder logic program which can take the analog and digital inputs and

make decisisions. This decision making process can control a water

treatment process called chemical pacing or it can operate a standby

generator. Within the last 8 or so years, SCADA manufacturers have

started to incorporate some of this functionality into the RTUs.

Previously that functionality was accomplished at the master station

level on a limited basis. The

PLC has all those abilities with some small differences, but one major

difference is that PLCs are programmable. The program is usually a

ladder logic program which can take the analog and digital inputs and

make decisisions. This decision making process can control a water

treatment process called chemical pacing or it can operate a standby

generator. Within the last 8 or so years, SCADA manufacturers have

started to incorporate some of this functionality into the RTUs.

Previously that functionality was accomplished at the master station

level on a limited basis.

RTU

The

RTU can look much more different than a PLC or some PLC manufacturers

call their PLCs an RTU. This is where the water starts to get a little

muddy. In the past and still today they usually are larger and a lot of

times they are much larger and mounted in large racks or cabinets. Many

people would question why an RTU would be used over a PLC, but

generally the true RTU analog, digital, and control inputs and outputs

are a more hardened type of connection and less susceptible to

electrical interference and surges. In addition, because the RTU

usually does not have programming involved, the RTU is cheaper to

purchase and easier to get up and running and maintain. The

RTU can look much more different than a PLC or some PLC manufacturers

call their PLCs an RTU. This is where the water starts to get a little

muddy. In the past and still today they usually are larger and a lot of

times they are much larger and mounted in large racks or cabinets. Many

people would question why an RTU would be used over a PLC, but

generally the true RTU analog, digital, and control inputs and outputs

are a more hardened type of connection and less susceptible to

electrical interference and surges. In addition, because the RTU

usually does not have programming involved, the RTU is cheaper to

purchase and easier to get up and running and maintain.

How do you know when to choose an RTU or PLC?

That truly depends on the application. The more automation you desire,

the more likely you are to choose a PLC. The PLC performs local

automation through its internal programming so if communications to the

server(s) is lost, the program may still operate. Although RTUs have

come a long way, they are generally not involved in a great deal of

local automation. The City of Manassas has a few PLCs scattered

throughout the Water Plant, but the majority of the site equipment are

RTUs therefore this site is dedicated mostly to development and

training on RTUs. |

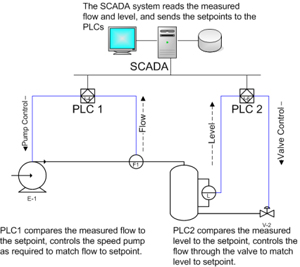

The

SCADA acronym stands for Supervisory Control and Data Acquisition.

SCADA systems are commonly used for utility companies such as electric,

water, and gas. The general idea for these systems is to be able to

monitor and control some level or status using programmable logic

controllers (PLCs) or remote terminal units (RTUs) and report it back

to a main server or master station. The master station can be

programmed to use this information to control other operations or just

to monitor the data. The data is distriubuted over a network to Human

Machine Interfaces (HMIs).

The

SCADA acronym stands for Supervisory Control and Data Acquisition.

SCADA systems are commonly used for utility companies such as electric,

water, and gas. The general idea for these systems is to be able to

monitor and control some level or status using programmable logic

controllers (PLCs) or remote terminal units (RTUs) and report it back

to a main server or master station. The master station can be

programmed to use this information to control other operations or just

to monitor the data. The data is distriubuted over a network to Human

Machine Interfaces (HMIs). The

HMI is merely a computer with special software allowing a graphical

user interface into the SCADA system. The screen shot (Left) is one

example of an HMI software package. There are several guages and input

fields on the screen. The input fields could be used to send commands

to the remote units to control flow of air, water, or some chemical.

The

HMI is merely a computer with special software allowing a graphical

user interface into the SCADA system. The screen shot (Left) is one

example of an HMI software package. There are several guages and input

fields on the screen. The input fields could be used to send commands

to the remote units to control flow of air, water, or some chemical. The

remote terminal unit (RTU) or programmable logic controller (PLC) is

the device out in the field that is collecting data and controlling

other devices such as valves or breakers. In general, the City uses

RTUs out in the field rather than PLCs (Left). There are significant

differences between the two although many manufacturers are building

them to be very similar. The typical RTU was designed to have inputs

for status such as door, valve, and breaker positions (digital data) as

well as flow rates or electrical current output (analog data). It will

also have some control functions to be able to open and close breakers

and valves and such.

The

remote terminal unit (RTU) or programmable logic controller (PLC) is

the device out in the field that is collecting data and controlling

other devices such as valves or breakers. In general, the City uses

RTUs out in the field rather than PLCs (Left). There are significant

differences between the two although many manufacturers are building

them to be very similar. The typical RTU was designed to have inputs

for status such as door, valve, and breaker positions (digital data) as

well as flow rates or electrical current output (analog data). It will

also have some control functions to be able to open and close breakers

and valves and such. The

PLC has all those abilities with some small differences, but one major

difference is that PLCs are programmable. The program is usually a

ladder logic program which can take the analog and digital inputs and

make decisisions. This decision making process can control a water

treatment process called chemical pacing or it can operate a standby

generator. Within the last 8 or so years, SCADA manufacturers have

started to incorporate some of this functionality into the RTUs.

Previously that functionality was accomplished at the master station

level on a limited basis.

The

PLC has all those abilities with some small differences, but one major

difference is that PLCs are programmable. The program is usually a

ladder logic program which can take the analog and digital inputs and

make decisisions. This decision making process can control a water

treatment process called chemical pacing or it can operate a standby

generator. Within the last 8 or so years, SCADA manufacturers have

started to incorporate some of this functionality into the RTUs.

Previously that functionality was accomplished at the master station

level on a limited basis. The

RTU can look much more different than a PLC or some PLC manufacturers

call their PLCs an RTU. This is where the water starts to get a little

muddy. In the past and still today they usually are larger and a lot of

times they are much larger and mounted in large racks or cabinets. Many

people would question why an RTU would be used over a PLC, but

generally the true RTU analog, digital, and control inputs and outputs

are a more hardened type of connection and less susceptible to

electrical interference and surges. In addition, because the RTU

usually does not have programming involved, the RTU is cheaper to

purchase and easier to get up and running and maintain.

The

RTU can look much more different than a PLC or some PLC manufacturers

call their PLCs an RTU. This is where the water starts to get a little

muddy. In the past and still today they usually are larger and a lot of

times they are much larger and mounted in large racks or cabinets. Many

people would question why an RTU would be used over a PLC, but

generally the true RTU analog, digital, and control inputs and outputs

are a more hardened type of connection and less susceptible to

electrical interference and surges. In addition, because the RTU

usually does not have programming involved, the RTU is cheaper to

purchase and easier to get up and running and maintain.